Grandfather Clock Prototype

Summary:

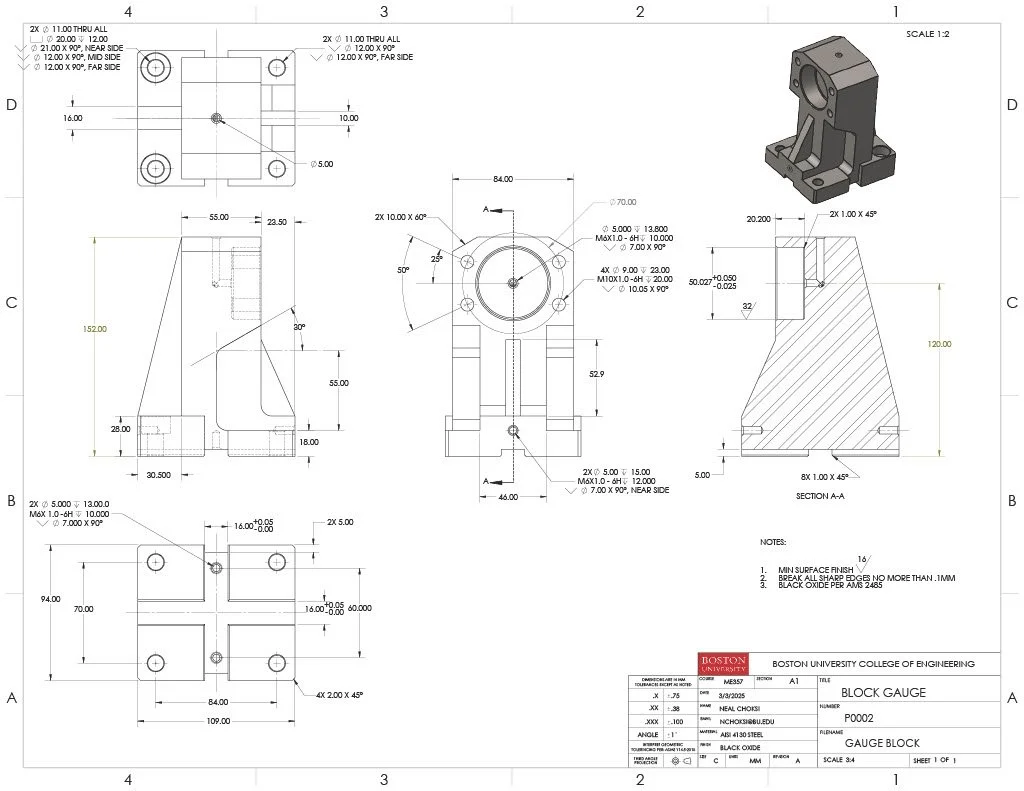

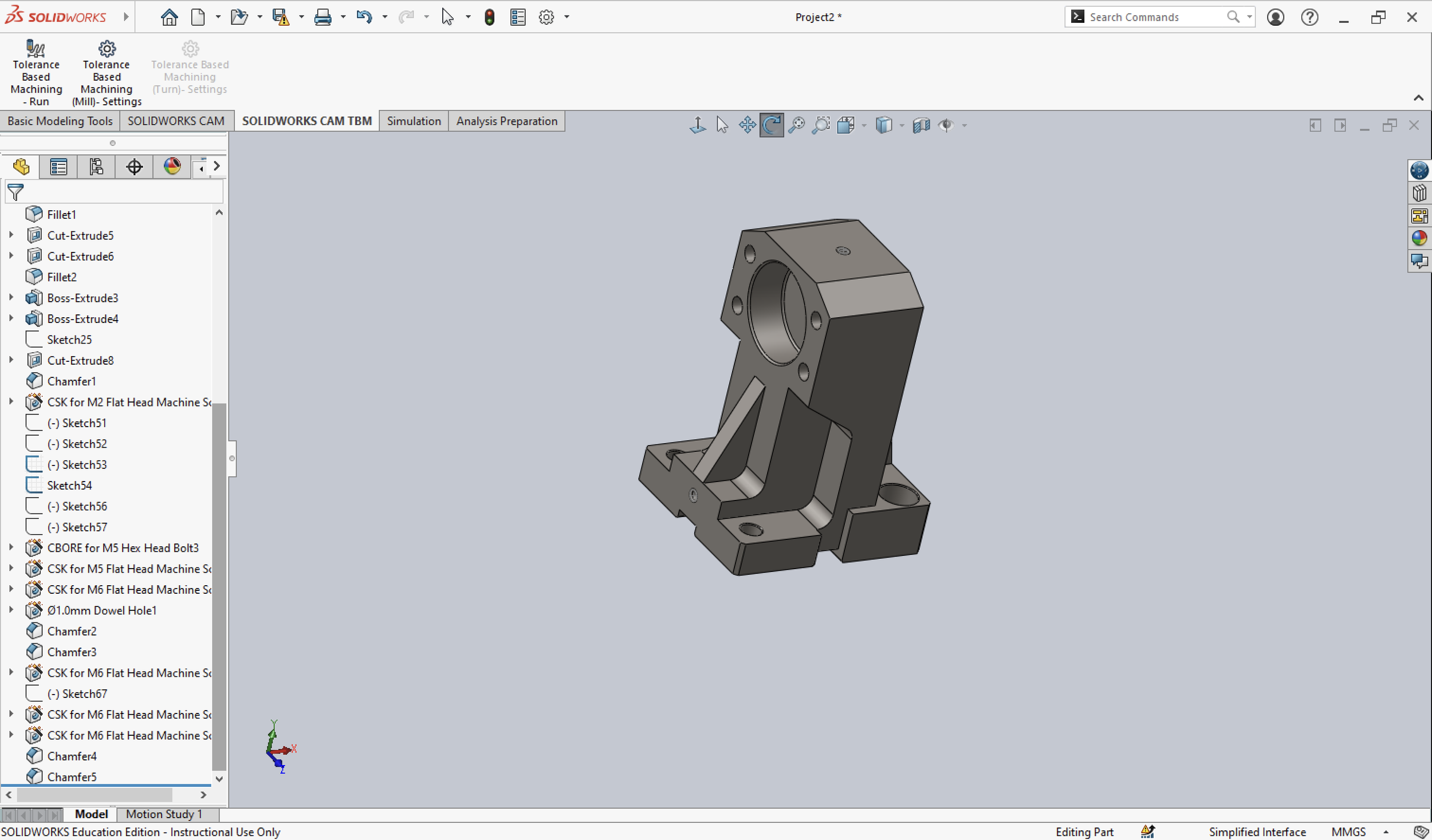

This block gauge project helped me develop a deeper understanding of fasteners and how different screw types are specified and implemented in mechanical design. Modeling the part required correctly designing and placing clearance holes, tapped holes, counterbores, and countersinks, each of which serves a different functional purpose depending on the fastener and assembly requirements.

One of the key lessons from this project was learning how to apply standard fastener callouts and hole specifications accurately. Selecting the correct hole size, depth, and head style for each screw type required referencing standards and ensuring the geometry was compatible with both the fastener and the surrounding features. Small mistakes in the hole definition quickly became apparent in the detailed drawings, reinforcing the importance of precision.

Creating the engineering drawing strengthened my understanding of how design intent is communicated to manufacturing. I learned how to clearly dimension fastener locations, apply proper section views, and use standard notation so that the part could be machined and assembled without ambiguity. This emphasized that good design is not just about modeling geometry, but also about creating documentation that others can reliably interpret.