Cap Project

Summary:

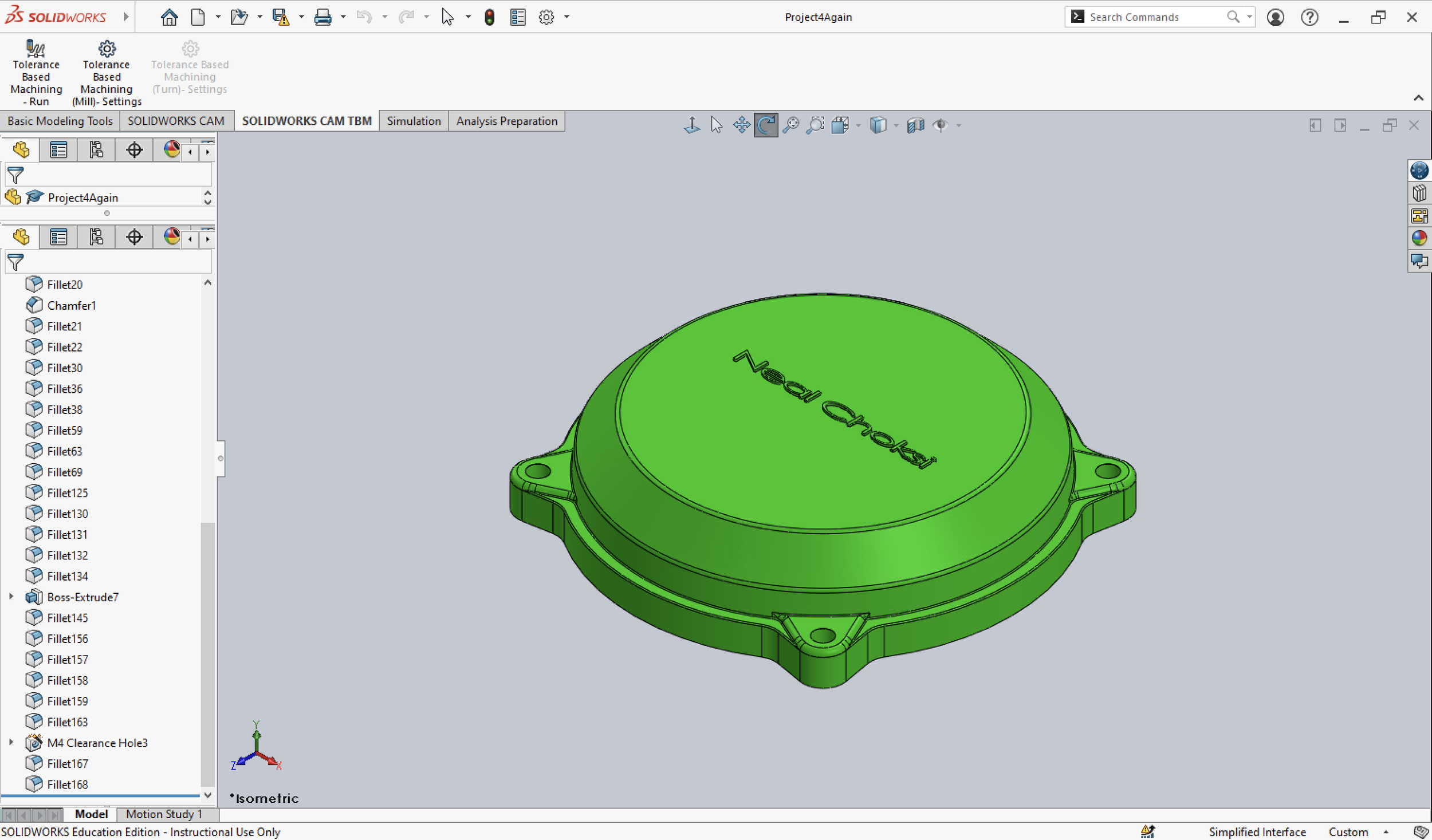

This cap project helped me understand how fillets and edge treatments influence both the functionality and manufacturability of a part. Applying consistent fillet radii across multiple features required careful planning, especially when transitioning between flat faces, curved surfaces, and mounting tabs. I learned that poorly planned fillets can create rebuild errors or interfere with neighboring features, making feature order and selection critical.

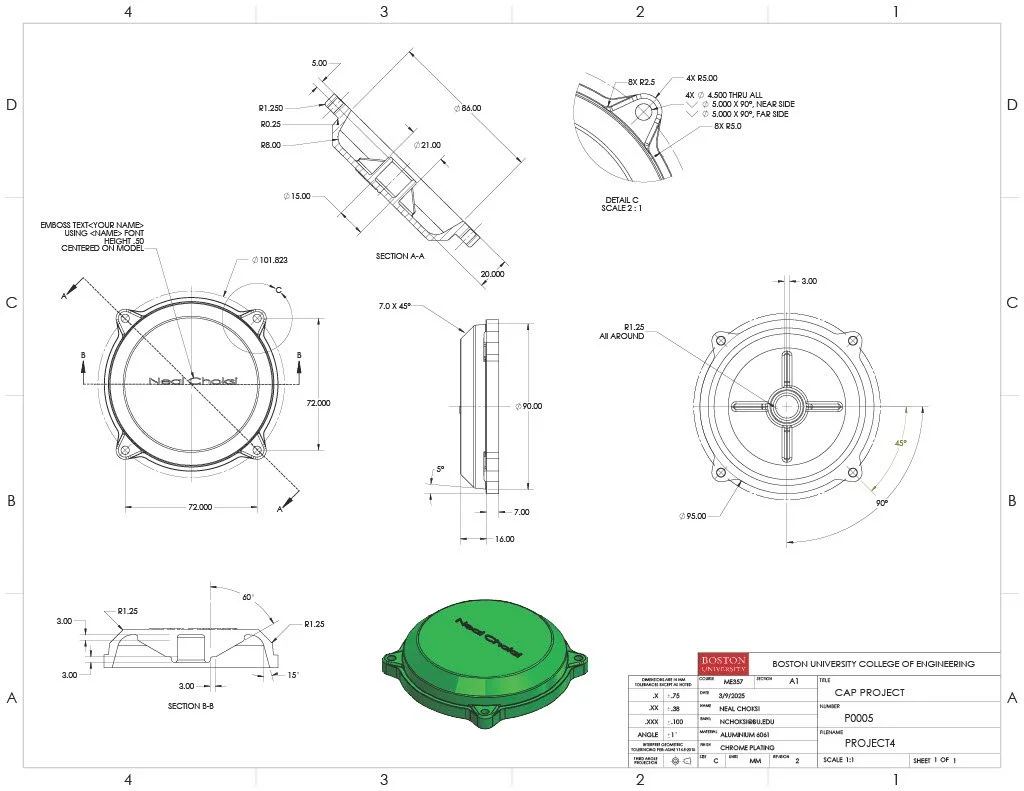

Creating the detailed drawing reinforced the importance of clear dimensioning and proper annotation. I gained experience specifying radii, chamfers, section views, and tolerances in a way that clearly communicates design intent to manufacturing. Adding text embossing and maintaining symmetry also required attention to reference geometry and sketch constraints.

Overall, this project improved my ability to model clean, well-finished parts that balance aesthetics, strength, and manufacturability. It emphasized how small geometric details—like fillet size and placement—play a major role in both structural behavior and professional-quality design documentation.