CamLens Prototype

Summary:

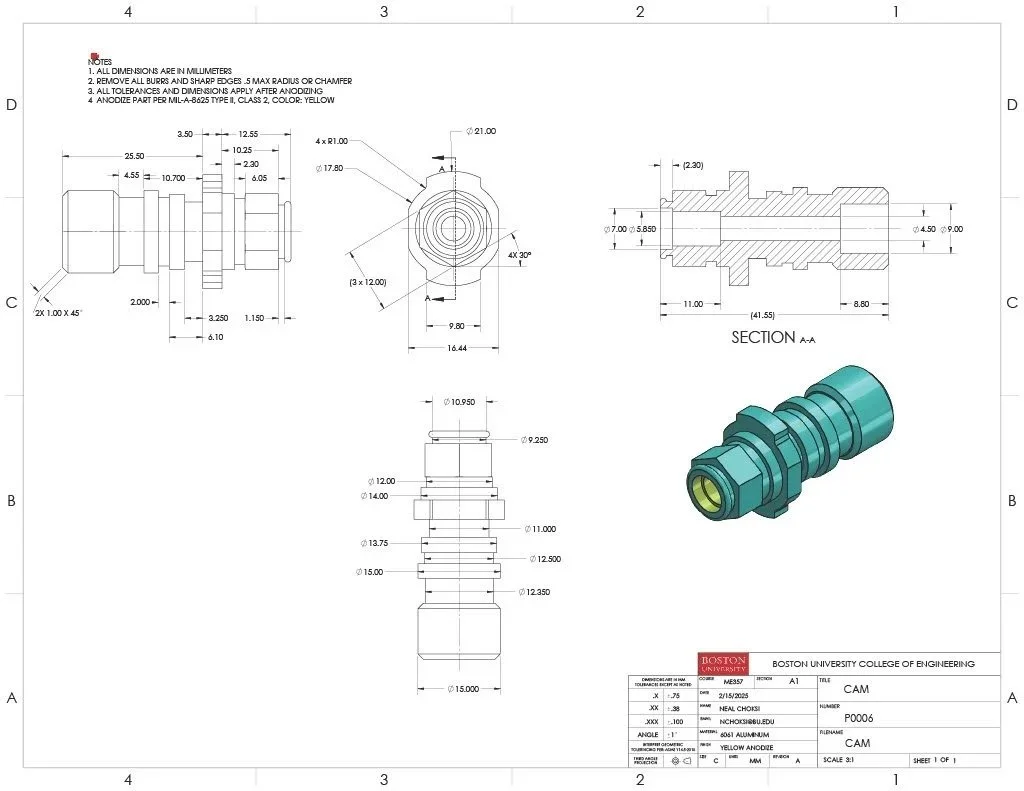

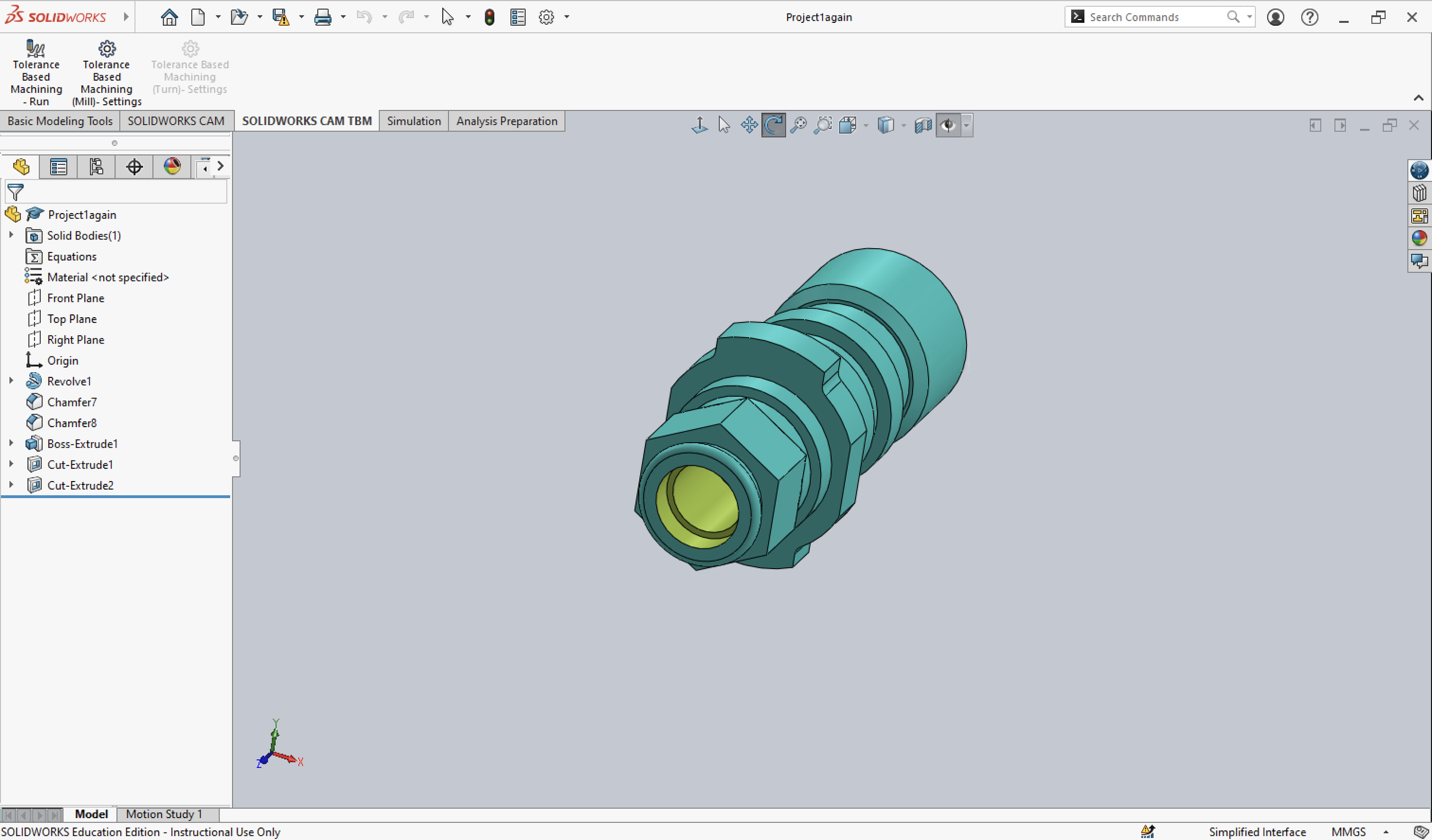

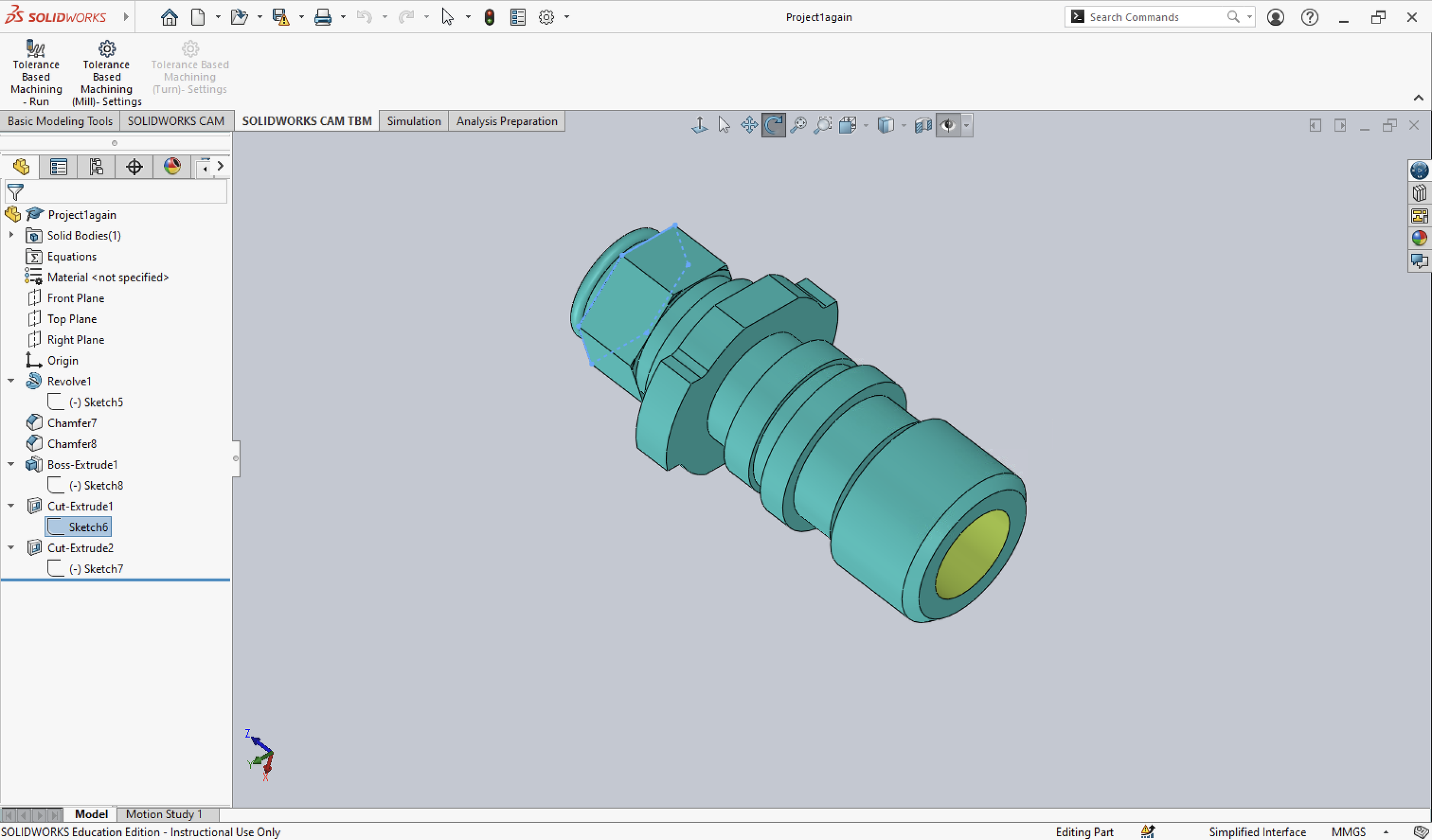

This project involved modeling a camera lens component in SolidWorks with a focus on manufacturability and feature accuracy. The part was built using a combination of revolved geometry, extruded bosses, and multiple cut features to achieve the stepped cylindrical profile, threaded regions, and internal bores required for a functional lens housing. Careful attention was paid to maintaining concentricity and consistent reference geometry throughout the design.

One of the main challenges was managing feature order and dependencies as the model became more complex. Small changes to early sketches often affected downstream features, which required reorganizing the feature tree and rebuilding sketches with more robust constraints. Another challenge was correctly modeling chamfers, transitions, and internal cut features without over-constraining the part or creating rebuild errors.